SAP PP TUTORIALS-

SAP MRP Methods in PP-(Material Requirement Planning): A Step-by-Step Guide-

Introduction-

SAP MRP Methods in PP-(Material Requirement Planning)-: Overview

In SAP HANA AND ECC 6.0 Material Requirements Planning (MRP) is a Important function in SAP. In SAP, Material Requirements Planning (MRP) can be executed in two ways:.

METHOD1-

-1)-Online (Foreground) MRP Execution-Used for immediate planning and quick analysis.and Suitable for small datasets or testing MRP results.

FOLLOW STEPS-

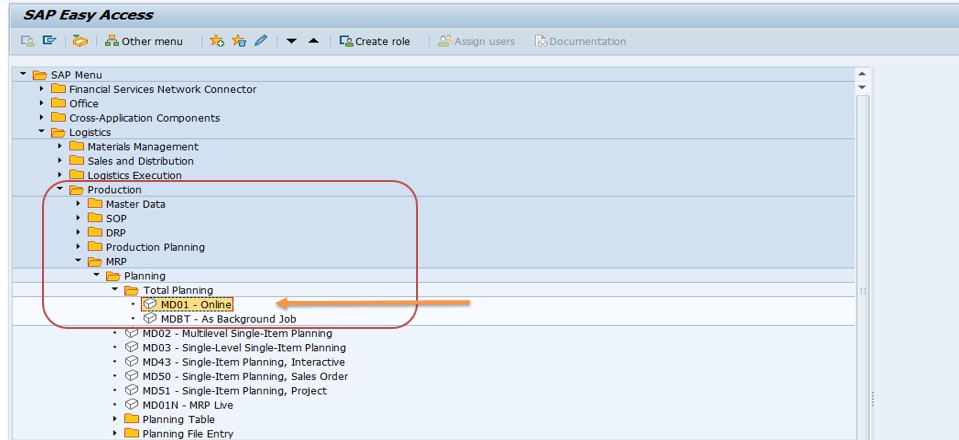

SAP Menu Path → MD01 or go to Logistics → Production → MRP → Planning → Total Planning → MD01-online.

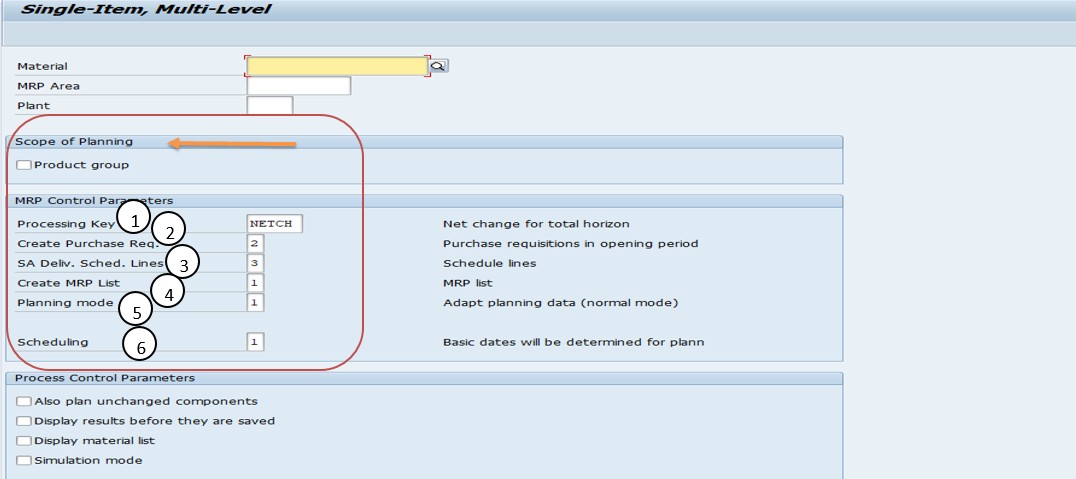

-MRP Parameters in the Processing Tab-

-1)Processing Key-

*)NETCH (Net Change for Total Horizon)-MRP only plans materials that have had changes since the last run (Example-stock changes, sales orders, purchase orders)..

*)NETPL (Net Change in Planning Horizon)-MRP runs for materials changed within a defined planning horizon..

*)NEUPL (Regenerative Planning)-Plans all materials, regardless of changes, leading to a longer runtime..

-2)Create Purchase Requisitions-

*)1(Create Purchase Requisitions)-MRP directly generates purchase requisitions for externally procured materials..

*)2(Create Planned Orders)-MRP generates planned orders instead of purchase requisitions. Users must convert planned orders to purchase requisitions manually..

*)3(No Purchase Requisitions, Only Planned Orders)-No purchase requisitions are created; MRP only generates planned orders..

-3)SA (Scheduling Agreement) Delivery Schedule Line-

*)1(Create Delivery Schedule Lines)-Generates delivery schedules for open scheduling agreements..

*)2(Do Not Create Schedule Lines)-Does not create schedule lines; only creates purchase requisitions..

-4)Create MRP List-

*)1(Create MRP List)-Stores the MRP results in an MRP list (MD05, MD06)..

*)2(No MRP List)-No MRP list is stored, but results can be seen in the Stock/Requirements list (MD04)..

-5)Planning Mode-

*)1(Adjust Planning Data)-Keeps existing planned orders and only updates changes..

*)2(Re-explode BOM and Routing)-Deletes existing planned orders and reprocesses the entire BOM..

*)3(Delete and Recreate Planning Data)-Deletes all existing planning data and creates new orders from scratch..

-6)Scheduling-

*)1(Basic Dates Scheduling)-Calculates planned order dates without considering capacity constraints..

*)2(Lead Time Scheduling and Capacity Planning)-Uses detailed scheduling, considers work center capacity, and determines precise dates..

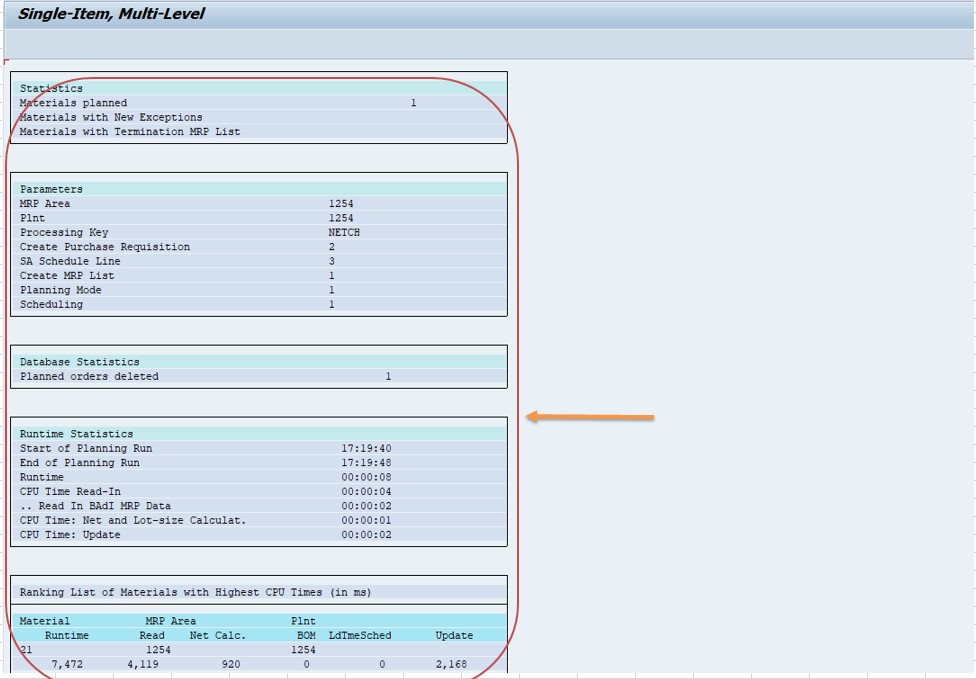

SAVE-

METHOD2-

-2)-Running MRP in Background (Batch Job Execution)-This method is useful for large-scale processing, especially in a production environment(Used for large datasets, company-wide planning, or night batch jobs)

FOLLOW STEPS-

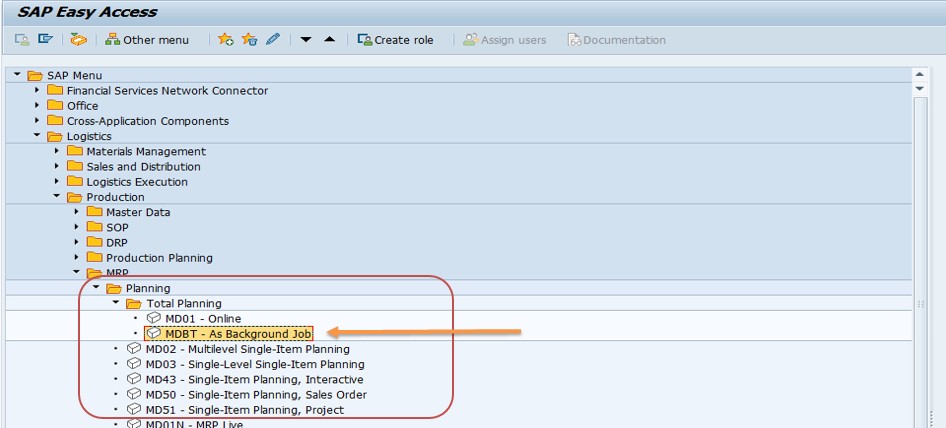

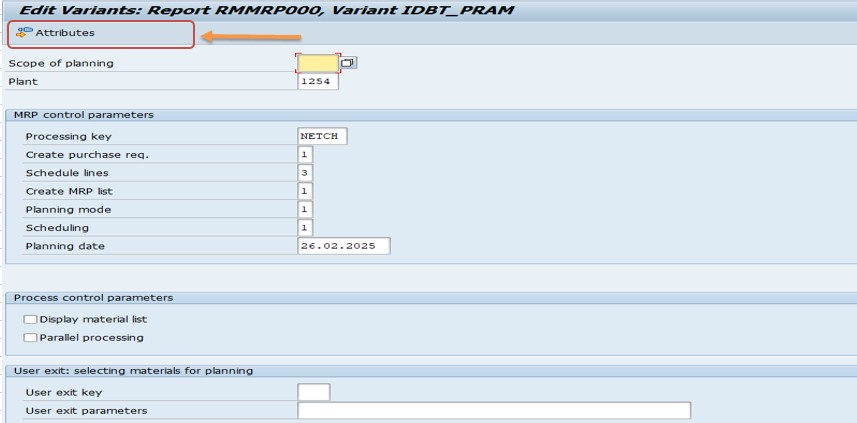

SAP Menu Path → MD01 or go to Logistics → Production → MRP → Planning → Total Planning → MDBT-As Background Job

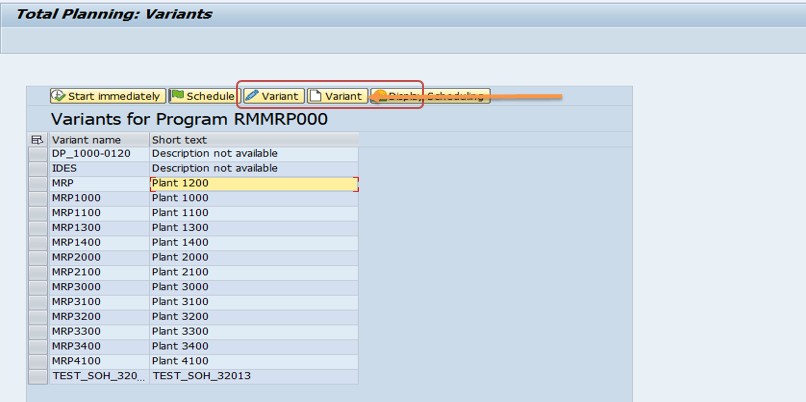

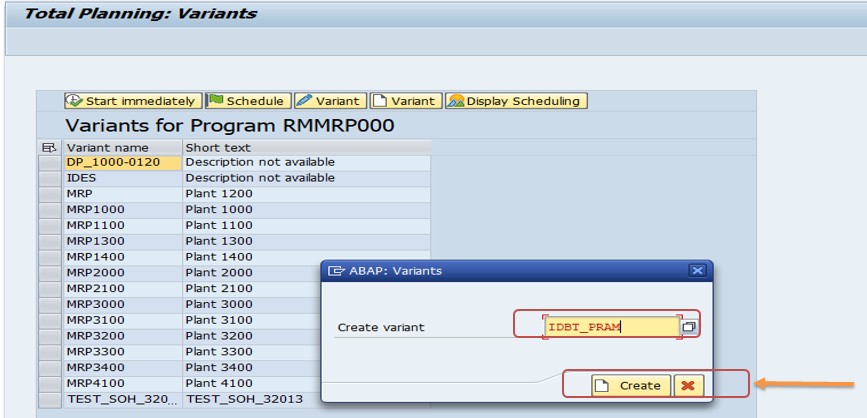

THEN SELECT CREATE VARIANT BUTTON-

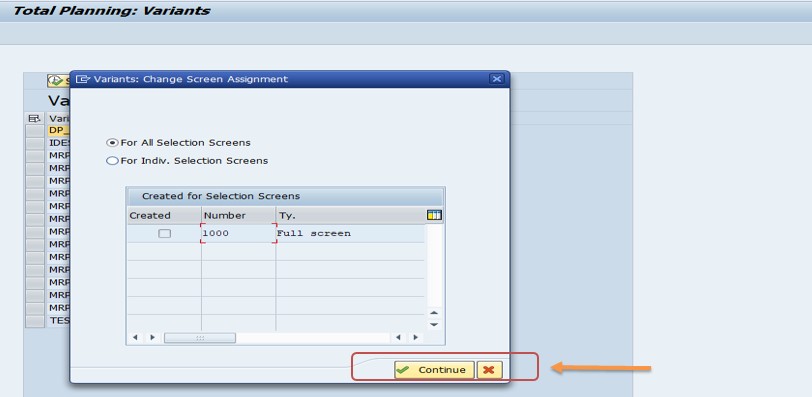

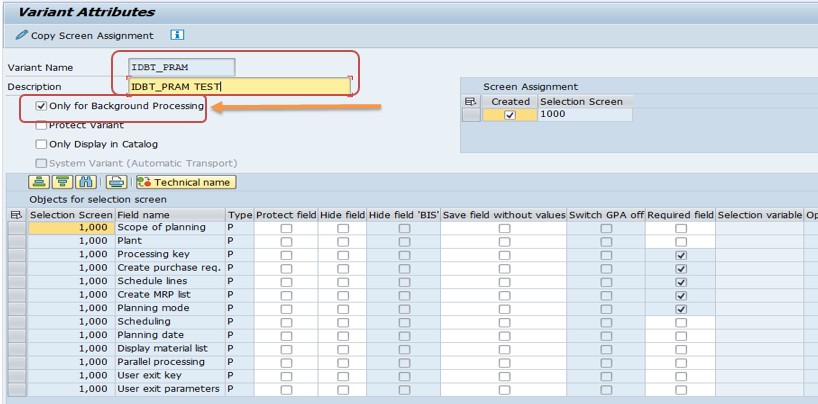

THEN SELECT CANTINUE BUTTON- THEN CLICK ON ATTRIBUTES

THEN SELECT ONLY FOR BACKGRAOUND TICK-SAVE

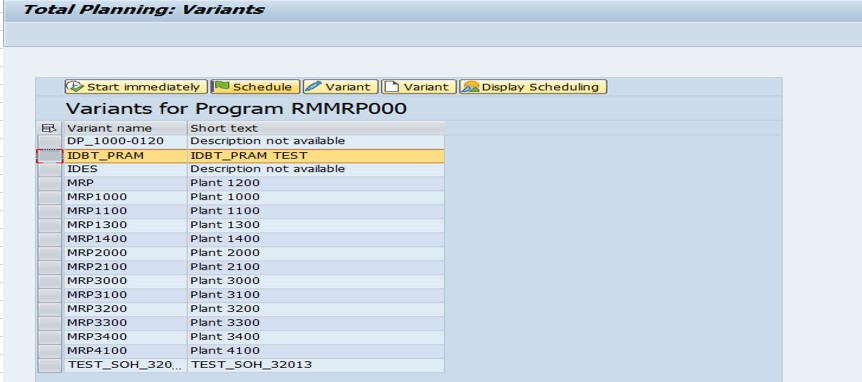

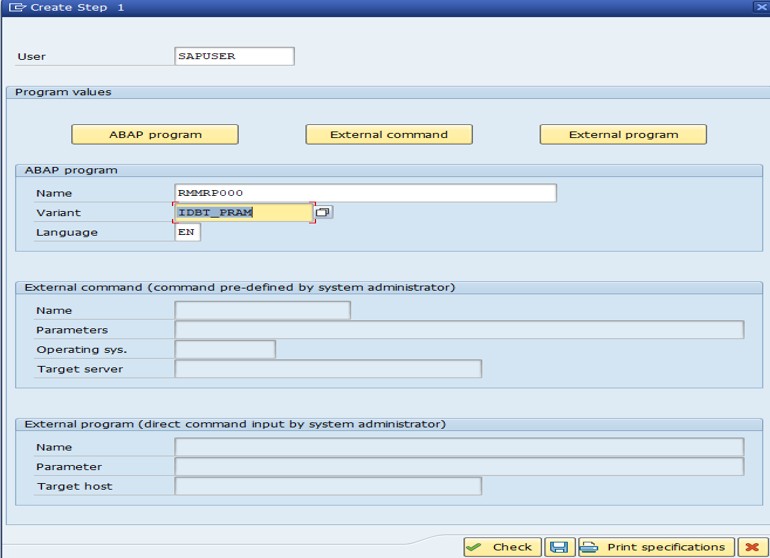

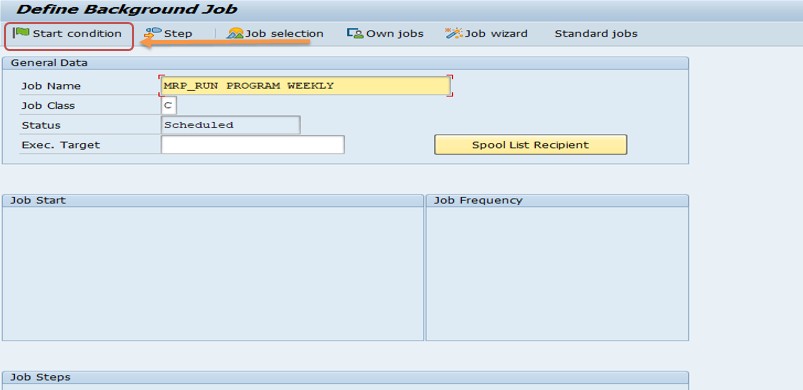

THEN GO TO TCODE-SM36 - THEN CLICK CHECK BUTTON FILL-NAME(RMMRP000),VARIANT-IDBT_PRAM, THEN GO TO BACK

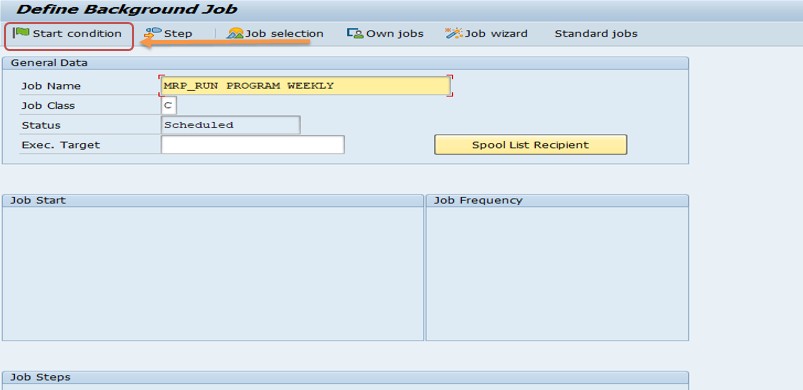

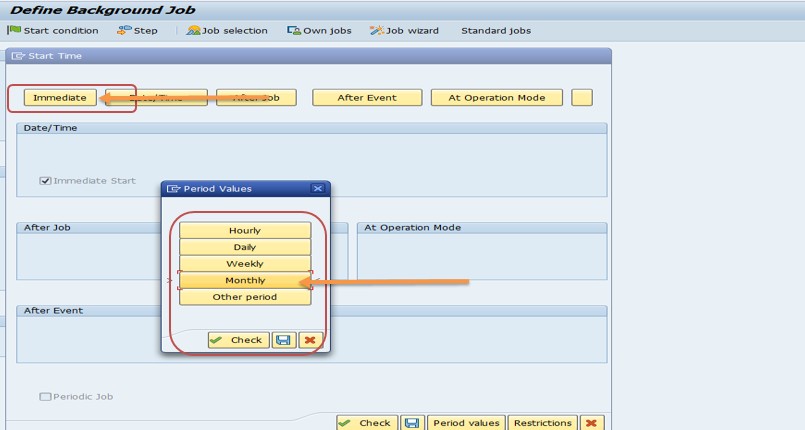

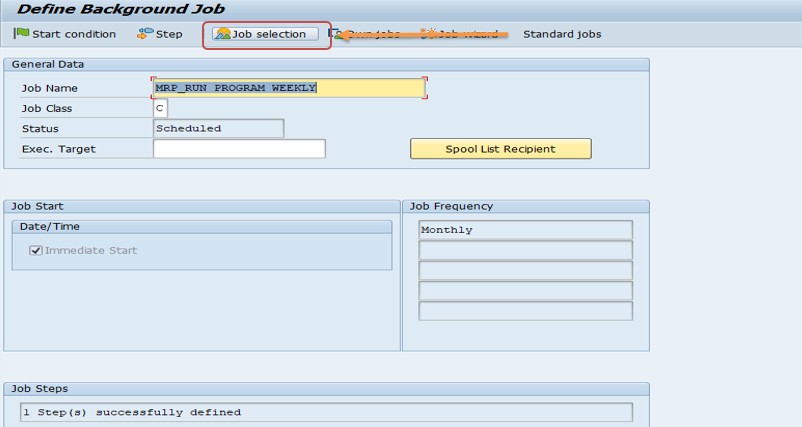

SAVE THEN CLICK ON START CONDITION BUTTON-THEN SELECT IMMEDIATE BUTTON-THEN CLICK PERIODS VALUES-SELECT MONTHLY VALUES- SAVE

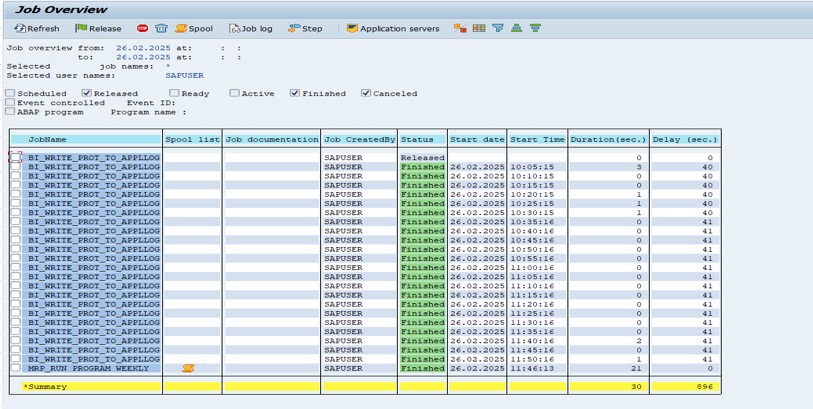

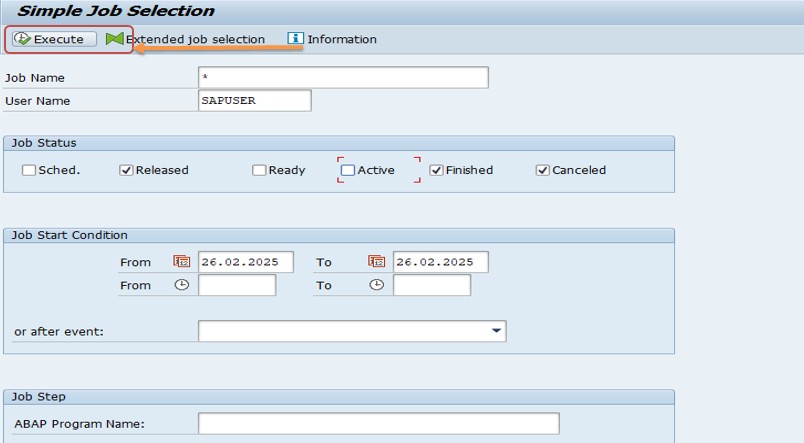

SELCET-JOB SELECTION-BUTTON-SELECT EXECUTE BUTTON

SEE JOB OVERVIEW-